Customized aluminum parts play a crucial role in automotive performance across various industries served. They improve efficiency, reduce weight, and enhance durability. The global automotive aluminum market, valued at USD 32.6 billion in 2024, is projected to grow to USD 61.3 billion by 2033. This growth reflects aluminum’s lightweight properties, which lead to better fuel efficiency.

Key Takeaways

- Customized aluminum parts significantly reduce vehicle weight, improving fuel efficiency by up to 2.7 miles per gallon.

- Aluminum’s natural corrosion resistance enhances vehicle durability, leading to lower maintenance costs and longer lifespans.

- The automotive aluminum market is rapidly growing, driven by the demand for lightweight materials in electric vehicles and mass production.

Key Automotive Components

Engine Components

Customized aluminum parts significantly enhance engine performance. Common types of aluminum engine components include:

- Aluminum alloy engine blocks

- Cylinder heads

- Pistons

- Connecting rods

- Gears

These components benefit from aluminum’s lightweight nature, which reduces overall vehicle weight and improves acceleration. The use of aluminum also enhances thermal management, allowing engines to operate more efficiently.

Transmission Parts

Aluminum plays a vital role in transmission systems. Customized aluminum transmission parts contribute to improved vehicle performance through several key features:

- An aluminum transmission housing provides a good balance between strength and weight, enhancing fuel efficiency and reducing energy losses.

- Aluminum’s thermal conductivity helps maintain optimal transmission temperatures, ensuring smooth operation.

Powertrain applications, such as transmission casings and engine mounts, rely heavily on aluminum due to its strength and thermal resistance. Additionally, aluminum extrusions in heat exchangers and radiators support effective thermal management in both internal combustion and electric vehicles.

Chassis and Structural Elements

Customized aluminum chassis elements offer numerous structural advantages compared to traditional materials. The following table outlines these benefits:

| Advantage | Description |

|---|---|

| Lightweight Yet Strong | Aluminum is about one-third the weight of steel, enhancing transport and installation efficiency. |

| Corrosion Resistance | Forms a protective oxide layer, extending lifespan and reducing maintenance needs. |

| Excellent Thermal and Electrical Conductivity | Effective in heat and electricity conduction, improving performance in various applications. |

| High Recyclability | Can be recycled with significantly less energy, promoting sustainability in construction. |

These advantages make aluminum an ideal choice for modern automotive applications, driving performance and efficiency in today’s vehicles.

Benefits of Customized Aluminum Parts

Weight Reduction

Customized aluminum parts significantly contribute to weight reduction in vehicles. Aluminum can reduce vehicle body structure weight by up to 40%, which is a substantial advantage over traditional materials like steel. High-strength steel can only achieve an additional 11% weight reduction. This reduction in weight does not compromise vehicle stiffness or performance.

- The Aluminum Association’s Transportation Group estimates that manufacturers can save about 525 pounds by using aluminum components. This weight savings can lead to an improvement of 2.7 miles per gallon in fuel economy.

- A 1% reduction in vehicle weight can save between 0.6% to 1.0% in fuel consumption. For every 100 kg reduction, vehicles emit approximately 5 g/km less CO2.

The table below summarizes the impact of aluminum on weight distribution:

| Evidence Description | Impact on Weight Distribution |

|---|---|

| Aluminum components can reduce vehicle weight by 40% | Enhances overall weight distribution, improving handling and performance |

| Each pound of aluminum used instead of steel reduces total weight | Directly affects weight distribution across the vehicle |

| Aluminum vehicles perform efficiently like steel counterparts but weigh less | Better weight management leads to improved fuel efficiency and lower emissions |

Improved Fuel Efficiency

The use of customized aluminum parts directly correlates with improved fuel efficiency. The automotive aluminum market is projected to grow significantly, with a market size valued at $86.88 billion in 2024 and expected to reach $197.93 billion by 2032. This growth is driven by stringent fuel efficiency regulations that require automakers to reduce vehicle weight.

A recent study by the EDAG Group indicates that an all-aluminum vehicle can reduce body mass by over 40%, leading to an 18% improvement in fuel economy. This significant enhancement in miles per gallon (MPG) illustrates the effectiveness of aluminum in increasing vehicle efficiency.

- Lightweight materials, including aluminum, have been increasingly adopted in vehicle design to enhance energy efficiency and reduce fuel consumption.

Enhanced Durability and Corrosion Resistance

Customized aluminum parts offer enhanced durability and corrosion resistance, making them ideal for automotive applications. Aluminum has a natural oxide layer that protects it from rust, which significantly enhances vehicle longevity.

- Custom aluminum parts are often treated with special coatings to prevent rust and oxidation, ensuring they perform well in harsh environments.

- Aluminum’s natural resistance to corrosion leads to fewer maintenance concerns and a longer product lifespan compared to steel, which requires treatment and regular inspections for rust.

The table below highlights the durability benefits of aluminum:

| Evidence Description | Impact on Durability |

|---|---|

| Aluminum has a natural oxide layer that protects it from rust | Enhances vehicle longevity |

| Custom aluminum parts are treated with special coatings | Prevents rust and oxidation, ideal for harsh environments |

| Aluminum is naturally resistant to corrosion | Leads to fewer maintenance concerns |

Real-World Applications

Electric Vehicles

Customized aluminum parts play a pivotal role in the development of electric vehicles (EVs). These parts help manufacturers enhance efficiency and extend driving range. Here are some key benefits of using aluminum in EVs:

- Customized aluminum parts reduce vehicle weight, leading to improved energy consumption.

- A weight reduction of 100 kg can enhance efficiency by approximately 3.6%.

- Lighter structures allow electric vehicles to utilize smaller battery packs, resulting in cost savings and increased range.

- The use of aluminum allows for significant weight reduction compared to steel. For example, the VW Golf is 187 kg lighter when constructed with aluminum.

Notable electric vehicles that utilize customized aluminum parts include:

| Vehicle | Aluminum Usage (kg) | Key Features |

|---|---|---|

| Tesla Model S | 190 | Aluminum-intensive body and chassis for improved range and performance. |

| Audi e-tron | 700 | Lightweight aluminum body enhances efficiency and includes battery housing. |

| Jaguar I-PACE | 300 | Aluminum architecture improves efficiency, driving dynamics, and safety. |

High-Performance Sports Cars

High-performance sports cars benefit immensely from customized aluminum parts. These vehicles prioritize speed and agility, making weight reduction crucial. As one expert noted, “One of the best ways to increase the speed of an object (or a vehicle) is to reduce how much it weighs.” Racing teams have long recognized the advantages of aluminum’s lightweight nature and strength-to-weight ratio.

- Aluminum alloys have been utilized in racecars since the late 19th century, indicating a long-standing relationship between the material and racing performance.

- The first racing vehicle with an aluminum body was introduced in 1899, showcasing early adoption of the material.

- The design of the first aluminum engine by Carl Benz in 1901 further emphasizes the importance of aluminum in enhancing vehicle performance.

The integration of customized aluminum components leads to significant performance gains, including:

- Aluminum components can weigh approximately 40% less than their steel counterparts, significantly impacting overall vehicle weight.

- Reducing vehicle weight enhances performance metrics such as acceleration, braking efficiency, and handling capabilities.

The introduction of cast aluminum wheels by Bugatti in 1924 exemplifies this trend. These wheels reduced unsprung weight, leading to improved handling and responsiveness. The reduction in mass allowed for faster acceleration, smarter braking, and higher cornering speeds without loss of control.

Mass Production Vehicles

Major automotive manufacturers increasingly implement customized aluminum parts in mass production vehicles. This shift reflects the industry’s commitment to improving efficiency and performance while maintaining cost-effectiveness. Recent projects have demonstrated significant weight savings through the conversion of traditional steel components to aluminum.

For instance, a C-segment SUV passenger door conversion from steel to aluminum resulted in a 45% weight savings. Similarly, a B-pillar project achieved a 35% weight reduction while maintaining structural integrity. These changes illustrate the effectiveness of aluminum in enhancing vehicle performance and safety.

Manufacturers utilize various processes to produce aluminum components efficiently:

| Manufacturing Process | Description |

|---|---|

| Additive Manufacturing | Involves building parts layer by layer from powdered aluminum, ideal for rapid prototyping. |

| CNC Machining | Uses automated tools for precise cutting and shaping of aluminum components. |

| Die Casting | Injects molten aluminum into molds for high precision and efficiency in mass production. |

The ongoing integration of customized aluminum parts in mass production vehicles showcases the material’s versatility and its critical role in advancing automotive technology.

Industries Served

Automotive Sector

The automotive sector heavily relies on customized aluminum parts for various applications. Key segments include:

- Passenger Vehicles: The lightweight nature of aluminum enhances performance and fuel economy.

- Commercial Vehicles: The strength-to-weight ratio improves safety and versatility in applications like engines and structural components.

These advantages make aluminum a preferred choice in automotive manufacturing, driving innovation and efficiency.

Lighting Industry

Customized aluminum parts play a significant role in the lighting industry. They are utilized in various applications, including:

| Application Type | Description |

|---|---|

| Architectural lighting fixtures | Design unique lamp bases, chandelier components, and wall mount sconces with intricate details. |

| Industrial electrical components | Create enclosures for transformers, switchgear, and other electrical equipment. |

| Customizable components | Design intricate brackets, connectors, and other components tailored to electrical needs. |

| Lighting Fixtures | Offers precision and durability for decorative and industrial lighting solutions. |

Anodized aluminum is favored for LED lamp shells due to its exceptional corrosion resistance, ensuring longevity in outdoor lighting solutions.

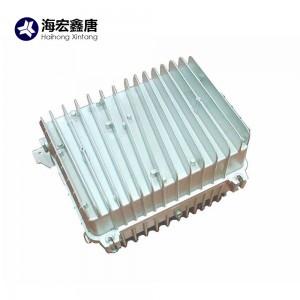

Telecommunication Sector

In the telecommunication sector, customized aluminum parts enhance infrastructure reliability. Key applications include:

- Antenna housings and support brackets

- Base station casings

- Heat sinks for cooling telecom equipment

- RF shielding components

- Waveguides and connectors

Aluminum’s precision and reliability enable the production of critical telecom components, ensuring long-term durability and cost-efficiency.

Customized aluminum parts are essential for driving automotive performance. They enhance vehicle safety, efficiency, and fuel economy. Key advantages include:

- High strength-to-weight ratios, crucial for weight reduction.

- Durability and cost-effectiveness, making them versatile in design.

The Automotive Aluminum Market is projected to grow significantly, driven by the rise of electric vehicles and consumer preferences for sustainable materials.

FAQ

What are the main advantages of using customized aluminum parts in vehicles?

Customized aluminum parts offer weight reduction, improved fuel efficiency, and enhanced durability, making them ideal for modern automotive applications.

How do aluminum parts contribute to electric vehicle performance?

Aluminum parts reduce vehicle weight, leading to better energy consumption and extended driving range for electric vehicles.

Are customized aluminum parts cost-effective for mass production?

Yes, customized aluminum parts provide cost savings through weight reduction and improved manufacturing efficiency, making them suitable for mass production vehicles.

Post time: Oct-02-2025