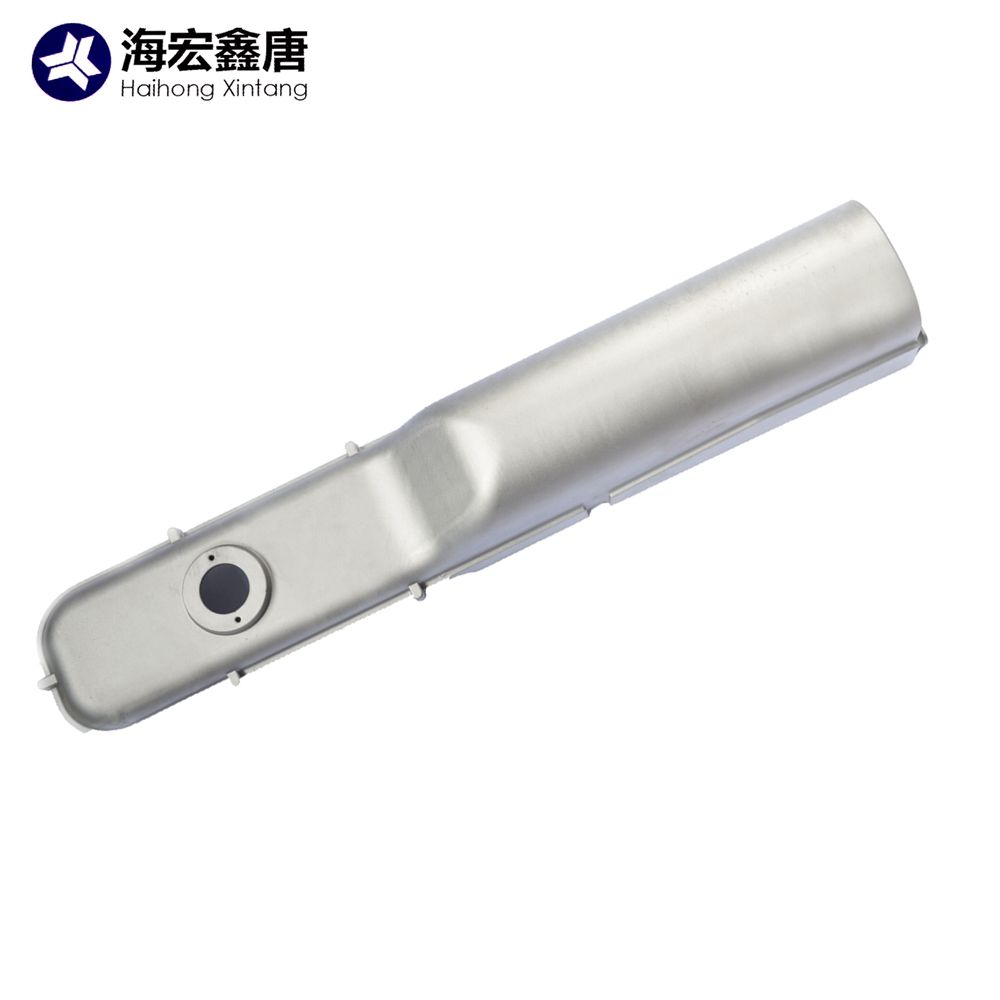

Factory source Custom Cnc Lathe Parts - Made in China aluminum sand die casting spare parts – Haihong

Factory source Custom Cnc Lathe Parts - Made in China aluminum sand die casting spare parts – Haihong Detail:

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Place of Origin:

-

Zhejiang, China

- Brand Name:

-

HHXT

- Machine Type:

-

Sewing Machine

- Type:

-

sewing machine parts

- Use:

-

Household

- Raw material available:

-

aluminum ADC1,ADC12, A380, AlSi9Cu3,etc

- Technology and Process:

-

high pressure die casting

- Secondary process available:

-

drilling, threading, milling, turning, CNC machining

- Surface finish available:

-

shot blasting, sand blasting, trivalent chromate passivation,etc.

- Tooling made:

-

inhouse

- Lead time:

-

35-55 days for mould, 25 days for product order

- Packaging:

-

carton, wooden pallet or per request of customer.

- Business type:

-

customizing, customized

- Drawing accepted:

-

stp, step, igs, dwg, dxf, pdf, tiff, jpeg files, etc.

- Application:

-

Machine industry

Product Description

Product Application

Aluminum industrial sewing machine parts

Application: Machine industry

As a professional producer of die casting, we can do according to customer’s drawing and specifications.

We are ready for your parts. Contact us to know more.

Certifications

About us

CNC Machining

We have 39 sets of CNC machining center and 15 sets of numerical control machine. High precision with little deformation.

Strict Quality Control

Every product will be tested for over six times before appearance. Each of our products is made of superior materials.

Shipping

Delivery time: 20~30 days after payment

Packing: gas bubble bag, carton, wooden pallet, wooden case, wooden crate. or as per customer’s requirement

Our factory

Related Products

OEM Sand Casting office chair base aluminum casting chair leg

Waterproof led flood street light housing

Aluminum die cast electronic parts

Product detail pictures:

Related Product Guide:

It is actually our accountability to satisfy your needs and effectively serve you. Your pleasure is our best reward. We're on the lookout forward for your stop by for joint growth for Factory source Custom Cnc Lathe Parts - Made in China aluminum sand die casting spare parts – Haihong, The product will supply to all over the world, such as: Rio de Janeiro , Pretoria , New Orleans , Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.