2019 China New Design Aluminum Threaded Sleeve - Metal punch die stamping process sheet metal parts – Haihong

2019 China New Design Aluminum Threaded Sleeve - Metal punch die stamping process sheet metal parts – Haihong Detail:

- CNC Machining or Not:

-

CNC Machining

- Type:

-

Drilling, Turning, Milling, Wire EDM, Broaching, Laser Machining, Etching / Chemical Machining, Other Machining Services, Rapid Prototyping

- Material Capabilities:

-

Bronze, Stainless Steel, Aluminum, Brass, Hardened Metals, Steel Alloys, Copper, Precious Metals, milling cnc

- Micro Machining or Not:

-

Micro Machining

- Place of Origin:

-

Zhejiang, China

- Model Number:

-

stamping processing

- Brand Name:

-

sokun

- Brand:

-

SOKUN

- Finish:

-

Zinc, Hot dip galvanized, Power coating, Nickel,Black anodizing

- Material:

-

Mild Steel,Stainless steel,Aluminum alloy, Brass

- Size:

-

According to customer''s requirement

- Precision Range:

-

0.05mm-0.2mm

- Service:

-

OEM/ODM/Customized/Design

- Delivery time:

-

Normally in 30-40 days.

- Trade Assurance:

-

Protect your order everything

- Package:

-

Cartons&pallets or according to customer''s requirement.

- stamping processing:

-

stamping processing

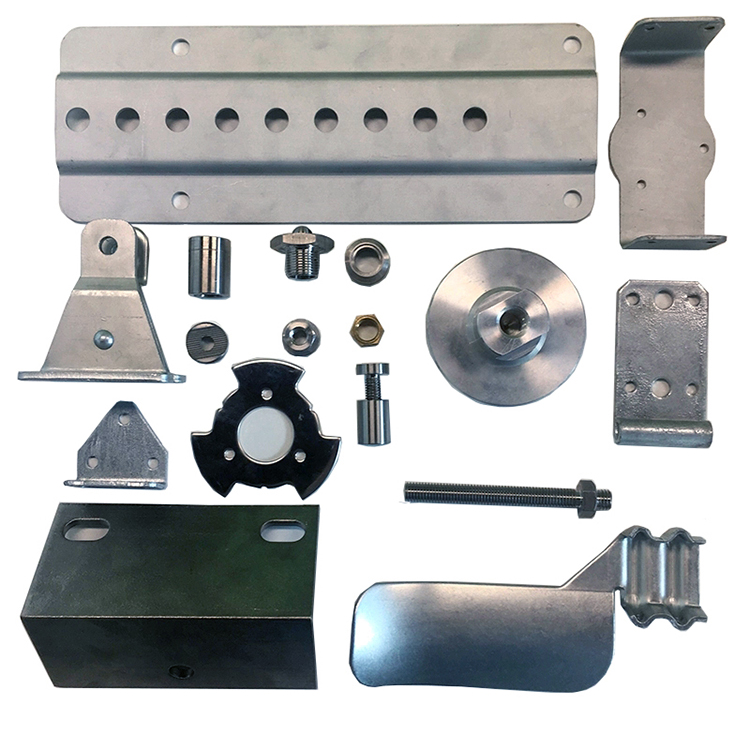

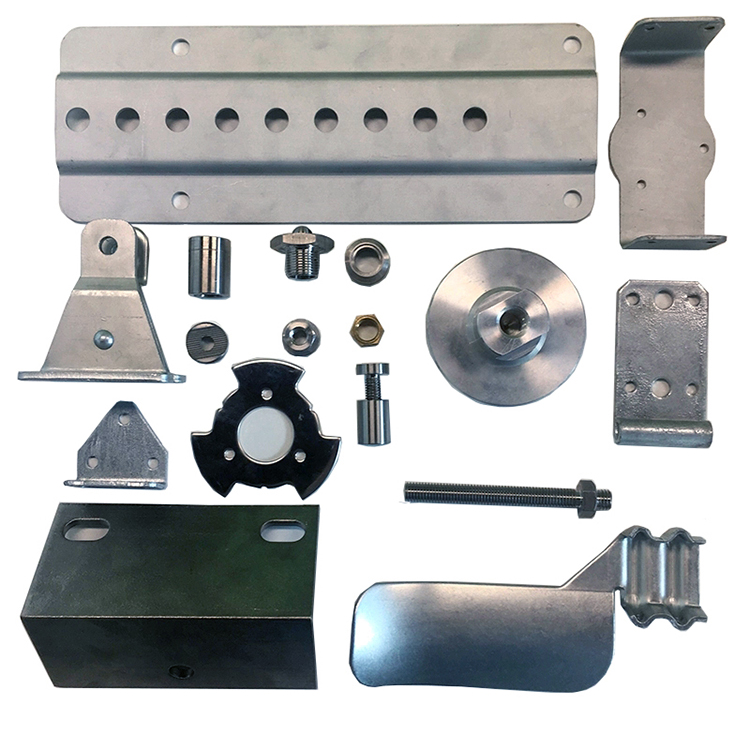

Product Description:

stamping processing

|

Item |

Description |

|

Product Name |

machined part |

|

Material |

Stainless steel:304,316. Steel:carbon steel. Aluminum alloy:6061,6063. |

|

Surface Treatment |

Anodizing, Polishing, Powder coating, Passivation, Sandblasting, Nickal plating,Zinc plating, Chrome plating, Heat treatment, Oxidation |

|

Applocation |

Electronic, auto, electric appliance, electrical machine, toy, medical treatment,electronic cigarette spare metal parts,loudspeaker box, furniture and fitness equipment and other industries. |

|

Design |

According to customer drawing or sample |

|

Equipments |

CNC punching machine, CNC milling machine, CNC turning machine,CNC machining center, Automatic lathe, Linear cutting, Grinding machine etc. |

|

Packing |

Inner-Plastic Bag; Outer -Standard Carton Box. |

|

File Format |

Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,DXF,IGS |

|

Service |

Warm and quick response service provided by the professional Export Sales Team with many years’ experience in handling exports to the US, Europe, Japan and other countries and regions. |

Stamping Parts and Machined Parts:

Factories and equipment

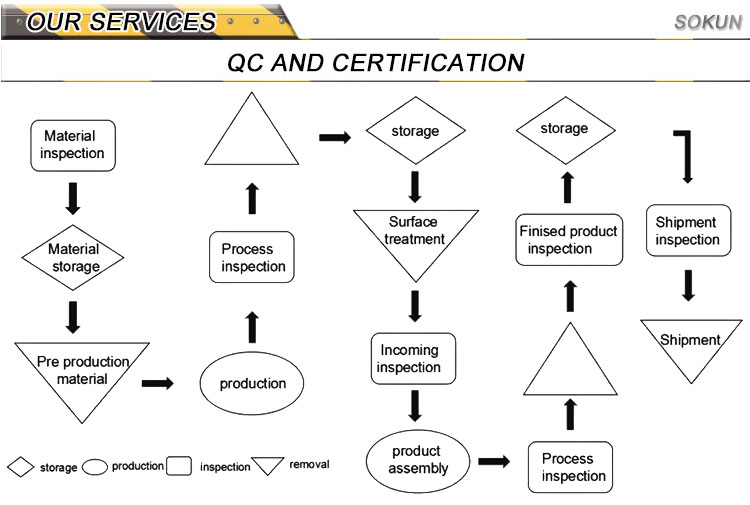

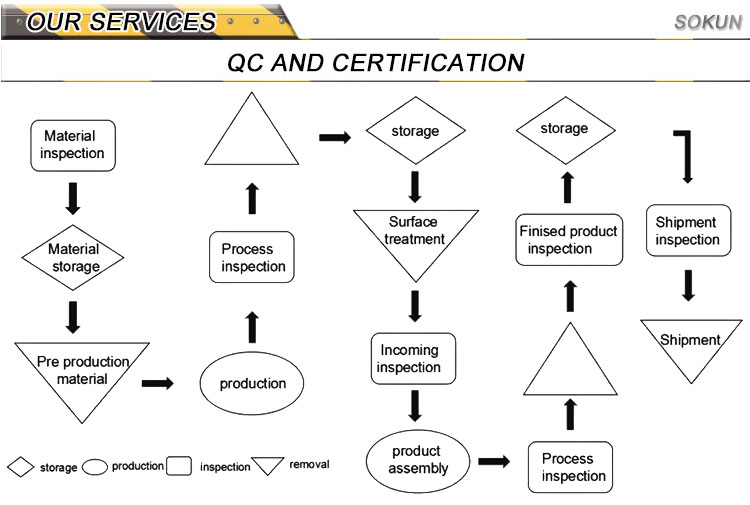

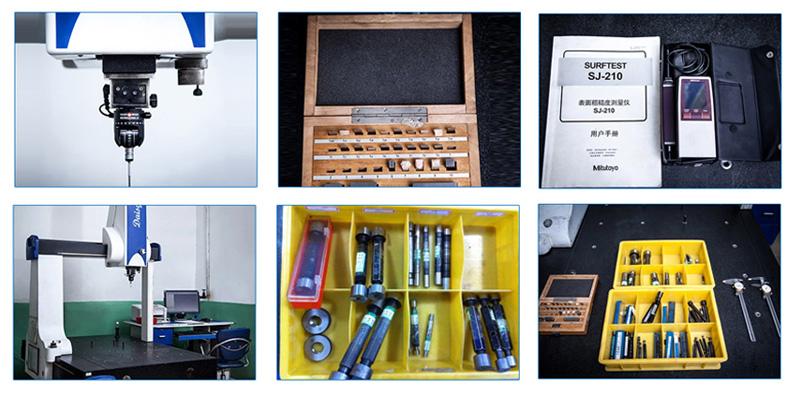

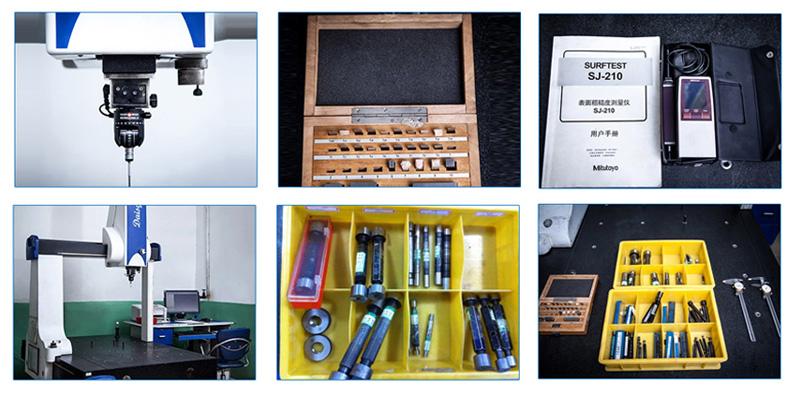

Testing & Control:

Detectability:

Production Workshop & Equipment:

The Way Of Shipping:

FAQ:

Q1.What is your main products?

A1:Our main products are stamping parts and machined parts.

Q2. How to ensure that every process’s quality?

A2:Every process will be checked by our quality inspection department which insures every product’s quality. In the production of products, we will personally go to the factory to check the quality of products.

Q3.How long is your delivery time?

A3:Our delivery time is generally 30 to 45 days. Or according to the quantity.

Q4. What is your payment method?

A4:30% value of T/T in advance and other 70% balance on B/L copy.

For small order less than 1000USD, would suggest you pay 100% in advance to reduce the bank charges.

Q5.Can you provide a sample?

A5:Sure, Our sample is provided after receiving the tooling cost and courier fees.

Product detail pictures:

Related Product Guide:

Along with the "Client-Oriented" small business philosophy, a rigorous high-quality handle system, highly developed producing machines and a powerful R&D group, we always supply high-quality products and solutions, fantastic services and aggressive costs for 2019 China New Design Aluminum Threaded Sleeve - Metal punch die stamping process sheet metal parts – Haihong, The product will supply to all over the world, such as: Swansea , Turkey , Munich , Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.